Thinking about fixing up your Nissan or maybe just need a replacement part? You might be wondering about the best way to go. Well, choosing recycled Nissan parts can be a surprisingly good move for the planet. It’s not just about saving a few bucks; it’s about making a choice that helps reduce waste and conserve resources. Let’s explore why recycled Nissan parts are eco-friendly and how they fit into a more sustainable future for your car.

Key Takeaways

- Using recycled Nissan parts helps keep usable components out of landfills, giving them a second life.

- Recycling car parts means we use fewer new raw materials, which saves energy and natural resources.

- Nissan vehicles often use materials like aluminum that are highly recyclable, making their parts good candidates for reuse.

- While Nissan has good recycling rates in Japan, there’s room to improve how other materials are reused globally.

- Opting for pre-owned Nissan parts supports a circular economy and is a smart choice for vehicle maintenance.

The Environmental Advantages of Recycled Nissan Parts

When you think about fixing up your Nissan, you might not immediately consider where the replacement parts come from. But choosing recycled parts is actually a pretty smart move for the planet. It’s not just about saving a few bucks, though that’s nice too. It’s about making a real difference in how much waste we create and how many new resources we have to dig up.

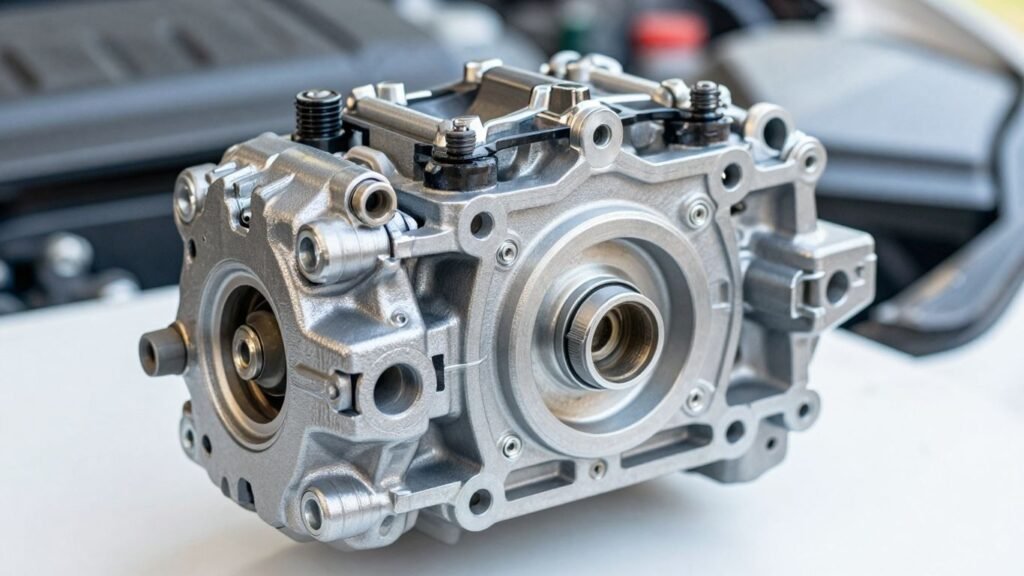

Reducing Landfill Waste With Reused Components

Every time a car part is tossed out, it has to go somewhere, and usually, that means a landfill. Landfills take up a lot of space and can sometimes leak harmful stuff into the ground. By using parts that have already been made and are still in good shape, we’re keeping them out of the trash heap. Think about bumpers, door panels, or even engine components – many of these can be cleaned up and used again. Nissan has been working on this, and in Japan, they collected and recycled around 93,000 bumpers in just one year. That’s a lot of plastic that didn’t end up buried.

Using pre-owned parts means we’re giving components a second life, which is way better than just throwing them away. It’s a simple idea, but it has a big impact on reducing the amount of stuff piling up in landfills.

Conserving Natural Resources Through Recycling

Making new car parts from scratch requires a lot of raw materials. We’re talking metals mined from the earth, plastics derived from oil, and other resources that aren’t exactly unlimited. When we recycle and reuse parts, we cut down on the need to extract these virgin materials. For example, aluminum can be recycled over and over with much less energy than it takes to make it new. This means less mining, less deforestation, and less disruption to natural habitats. It’s a way to keep more of the earth’s resources available for the future.

| Material Type | Energy to Recycle (vs. New) | Environmental Benefit |

|---|---|---|

| Aluminum | Significantly Lower | Reduced mining impact |

| Steel | Lower | Less ore extraction |

| Plastics | Varies | Less petroleum use |

Lowering Manufacturing Energy Consumption

Creating brand new parts from raw materials is an energy-intensive process. It involves mining, transporting raw materials, processing them, and then manufacturing the final product. Each of these steps uses a significant amount of energy, often from fossil fuels, which contributes to greenhouse gas emissions. When you opt for a recycled part, you’re skipping most of those initial, high-energy steps. The energy needed to refurbish or reuse an existing part is typically much, much lower. This directly translates to a smaller carbon footprint for your vehicle’s maintenance and repair.

Material Sustainability in Nissan Vehicles

When we talk about making cars, the stuff they’re made of really matters for the environment. Nissan uses a bunch of different materials, and some are definitely better than others.

The Role of Aluminum in Nissan’s Design

Nissan uses a good amount of aluminum, which is pretty great because it’s lighter than steel. This helps with fuel efficiency, and the best part is that aluminum can be recycled over and over without losing its quality. Think of it like a magic material that way. It’s a big part of the car’s structure, like the chassis and other bits.

Challenges with Resin and Plastic Components

Now, plastics, or resins as they’re often called, make up a decent chunk of a car, around 15% by weight. The problem is, most of these plastics come from petroleum and don’t break down easily if they end up somewhere they shouldn’t. Nissan has started using some plant-based materials for interiors, which is a step, but the amount of recycled plastic they use in new cars is still pretty small. It’s tough to get away from petroleum-based stuff entirely.

Environmental Impact of Rare Earth Metals

Nissan is pushing into electric vehicles, which is good for reducing tailpipe emissions. But, these EVs need special metals, often called rare earth metals, like lithium and cobalt for their batteries. Mining these metals can cause some serious environmental headaches and social issues in the places where they’re dug up. Nissan says they work with groups to try and source these metals more responsibly, but the mining itself is still a tough process.

It’s a bit of a balancing act. While Nissan is trying to be greener with things like EVs and using aluminum, the raw materials needed for some of these technologies, especially the batteries, come with their own set of environmental challenges that are hard to ignore.

| Material | Approx. % of Vehicle Weight | Sustainability Notes |

|---|---|---|

| Steel & Aluminum | 74% | Aluminum is highly recyclable; steel production can be energy-intensive. |

| Resins (Plastics) | 15% | Mostly petroleum-based, slow to degrade; limited use of recycled or bio-based options. |

| Rare Earth Metals | Varies (EVs) | Essential for EV batteries, but sourcing can have significant environmental impacts. |

Nissan’s End-of-Life Vehicle Recycling Initiatives

When a Nissan vehicle reaches the end of its road, the company has some pretty solid plans in place, especially in its home country of Japan. It’s all about making sure as much of the car as possible gets a second life or is properly processed. Nissan has achieved an impressive recycling rate of over 99% in Japan, which is a big deal when you think about how much goes into making a car.

Recycling Successes in Japan

In Japan, Nissan’s end-of-life vehicle program is quite advanced. They’ve managed to recover and recycle a huge chunk of the materials from cars that are no longer on the road. This means less stuff ends up in landfills. For instance, plastic parts like bumpers and underbody panels can be either fixed up or ground down to make new components. In 2021 alone, Nissan processed around 93,000 bumpers in Japan through their recycling efforts. This high recovery rate shows a real commitment to closing the loop on vehicle materials.

Repurposing of EV Batteries

Electric vehicles, like the Nissan Leaf, have batteries that are a whole different ballgame. Once these lithium-ion batteries can’t hold enough charge for driving anymore, they aren’t just tossed aside. Nissan, through partnerships like the one with 4R Energy Corporation, is focused on giving these batteries a new purpose. They can be repurposed for energy storage in other applications, like providing backup power for emergency services or other stationary energy needs. It’s a smart way to handle a complex component and keep valuable resources in use.

Underutilized Recyclable Materials Globally

While Nissan has made great strides in Japan, there’s still room for improvement elsewhere. Many of the materials used in Nissan vehicles are indeed recyclable, but they aren’t always being fully utilized for new production in other parts of the world. This means there’s a lot of potential for expanding recycling programs and technologies globally. The company is working on developing new recycling methods to increase the range of materials that can be reused, aiming to cut down on the need for brand-new raw materials. It’s a work in progress, but the goal is to make recycling more widespread and effective beyond Japan’s borders.

The end-of-life stage of a vehicle is a critical point. How a car is handled when it’s done being driven significantly impacts its overall environmental footprint. Nissan’s efforts, particularly in Japan, demonstrate a strong capability in managing this stage responsibly, turning old cars into resources rather than waste.

The Lifecycle Impact of Nissan Components

When we talk about making sustainable choices for our vehicles, it’s easy to focus just on fuel efficiency or whether it’s electric. But the story of a car’s environmental footprint starts much earlier and goes much further than just what happens on the road. It’s about where the materials come from, how the car is put together, and how it gets to you. Thinking about the entire journey of a Nissan component, from raw material to finished product, gives us a clearer picture of its true impact.

Sourcing Raw Materials Sustainably

The journey of a Nissan part begins with the earth. Extracting raw materials like metals and minerals isn’t always a clean process. While Nissan does use materials like aluminum, which is great because it can be recycled over and over, they also rely on other resources. Some of these, like certain rare earth metals, can be tough to get without causing environmental disruption. Plus, the plastics used often come from fossil fuels. It really makes you wonder about the initial footprint before a single bolt is even tightened.

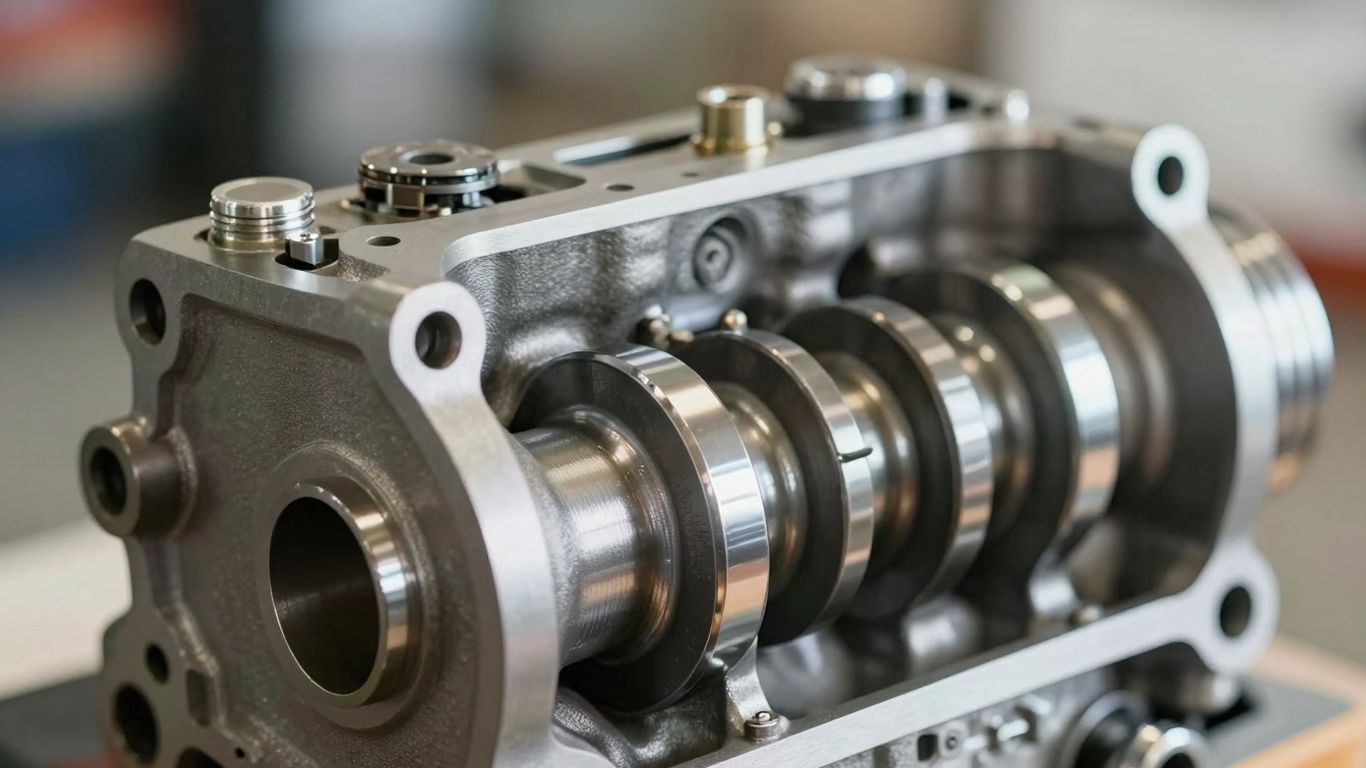

Manufacturing Processes and Energy Use

Putting a car together takes a lot of energy. Nissan’s factories use electricity to run their machinery, and unfortunately, not all of that electricity comes from clean sources. A good chunk still comes from fossil fuels, which adds to air pollution. Then there’s the painting process, which can release chemicals into the air. While Nissan has made some progress in reducing these emissions, there’s still a long way to go before these manufacturing steps are truly green. It’s a complex web of energy consumption and potential pollution.

Transportation Emissions of Parts

Once parts are made, they need to get to the assembly plants, and then the finished cars need to get to dealerships. This involves a lot of trucks and ships, which often run on diesel fuel. Even when Nissan uses trains, which are generally better for the environment than trucks, the sheer volume of parts and vehicles being moved around the globe adds up. These transportation emissions are a significant, though often overlooked, part of a car’s overall environmental story.

The path from raw material to your driveway is longer and more complex than many realize. Each step, from mining to assembly to shipping, carries its own environmental weight. Understanding this full lifecycle is key to appreciating the impact of the parts that make up your Nissan.

| Stage | Primary Environmental Concern |

|---|---|

| Material Extraction | Resource depletion, habitat disruption |

| Manufacturing | Energy consumption, air emissions |

| Transportation | Fossil fuel use, greenhouse gases |

Choosing Sustainable Options for Your Nissan

So, you’ve got a Nissan and you’re thinking about how to keep it running smoothly while also being kind to the planet. It’s a good thought to have, really. When it comes time to replace a part or even think about your next vehicle, there are definitely ways to lean into sustainability.

Benefits of Opting for Pre-Owned Parts

Think about it: instead of making a brand new part from scratch, which uses up energy and resources, why not use one that’s already out there? That’s the basic idea behind using pre-owned Nissan parts. When a car is retired, its usable components can often find a second life. This means less stuff going into landfills and less demand for new manufacturing. It’s a pretty straightforward win-win for the environment. Plus, these parts have already been tested by time and use, so you often know what you’re getting.

Supporting a Circular Economy

This whole idea of reusing parts is a big part of what people call a circular economy. Instead of the old ‘take-make-dispose’ model, it’s more about keeping things in use for as long as possible. When you choose a recycled Nissan part, you’re actively participating in this. It helps reduce the need to mine new metals or create new plastics, which can be pretty rough on the environment. It’s like giving materials another chance to be useful, which is a much smarter way to handle things.

Making Informed Choices for Vehicle Maintenance

When you’re looking at maintenance or repairs, asking about recycled or remanufactured parts is a good move. It might take a little extra effort to find them, but it’s worth it. You can often find these parts through specialized salvage yards or even some repair shops that focus on eco-friendly practices. It’s about being a bit more mindful with your car care.

Keeping your current Nissan running well with sustainable choices, like using pre-owned parts when possible, can significantly reduce its overall environmental footprint compared to constantly buying new. It’s a practical way to contribute to a healthier planet.

Ultimately, making these kinds of choices for your Nissan isn’t just about saving a few bucks, though that can happen too. It’s about being a more responsible car owner and doing your part to lessen the impact on the world around us. Every little bit helps, right?

Making the Smart Choice for Your Nissan

So, when it comes to keeping your Nissan running smoothly, thinking about recycled parts is a pretty good idea. It’s not just about saving a few bucks, though that’s nice too. It’s about doing your part to cut down on waste and the energy it takes to make brand new stuff. While Nissan’s overall sustainability journey is still a work in progress, especially outside of Japan, choosing recycled components is a solid step you can take right now. It helps reduce the demand for new materials and keeps usable parts out of the landfill. It’s a practical way to give your car a new lease on life while being a bit kinder to the planet.